Any gain/loss or material balance analyst will tell you how important it is for your liquid and gas measurement systems to remain accurate and consistent. After all, your product is measured to the 10,000th decimal place for a reason. Poor system performance leads to loss and no one likes a loser.

How do you ensure good measurement?

✔️ Continuous monitoring and calibration.

✔️ Higher quality equipment and manufacturing.

Monitoring

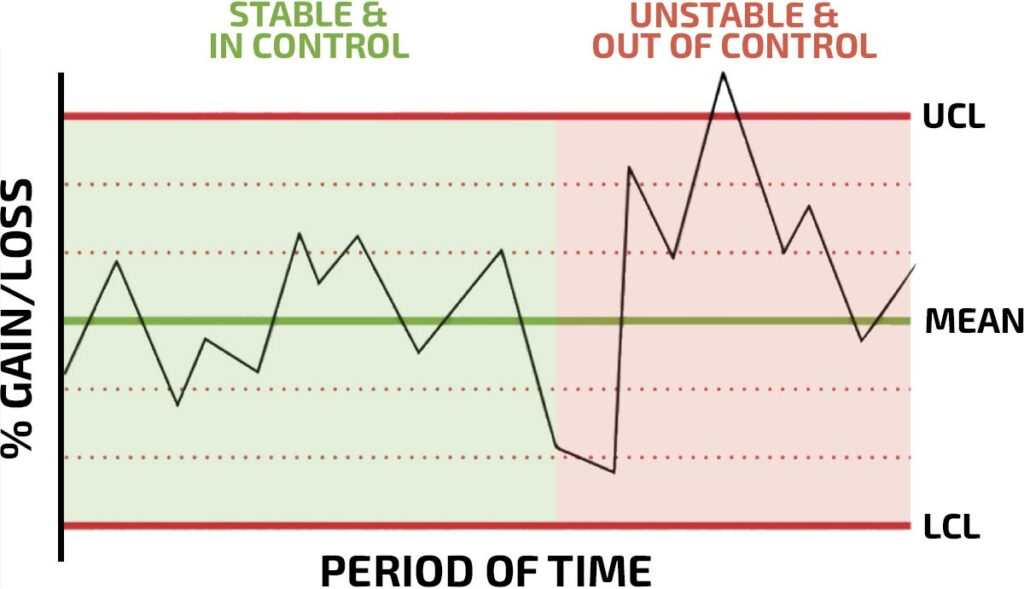

One of the most common methods for monitoring system performance looks at gain and loss as a percent of throughput over time. This determines if the system is stable AND in control.

Stability vs Control

✔️ Stable: Data moves randomly above and below the mean.

✔️ In Control: Data is within established upper and lower limits.

Equipment

When a system flies off the handle, most of the time it’s due to measurement inaccuracies, rather than an actual physical gain or loss. These inaccuracies are often caused by poorly built equipment.

Measurement system fabricators with low standards and lack of electrical and instrumentation experience can cause unnecessary backend costs during installation or after the system loses control.

A one-stop shop with experience manufacturing complete metering systems will undoubtedly help to maintain control and stability in the field. In an environment filled with uncertainty, you can be certain that a ReadyFlo system is built and tested at the highest level of quality and integrity.

ReadyFlo Systems engineers, designs, and builds turnkey liquid and gas measurement and control systems, including in-house instrumentation, electrical (I&E), and functional testing.

Learn more about ReadyFlo’s full range of capabilities or contact us today.